Your Cart is Empty

3D Printing additive manufacture

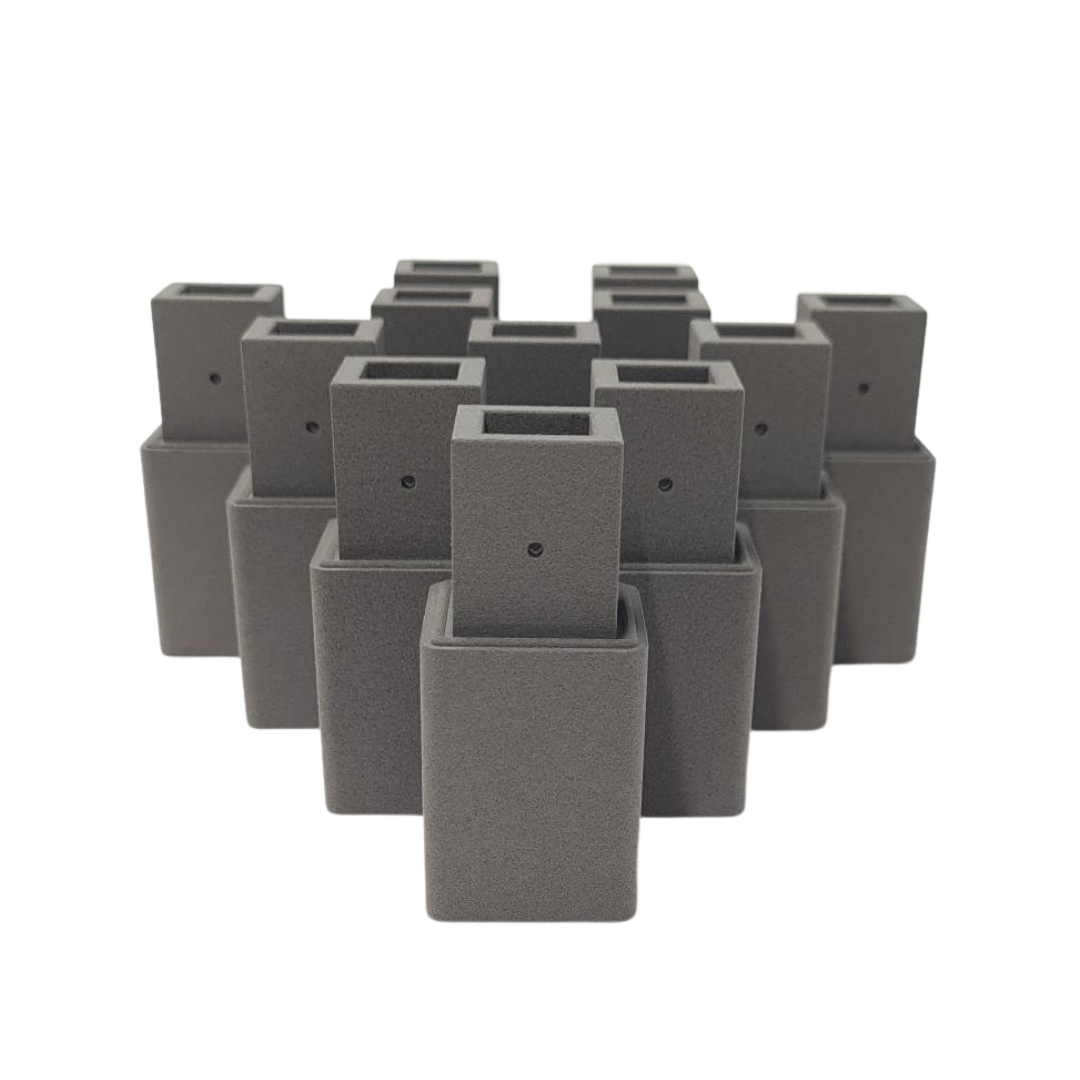

PLASTIC PARTS MANUFACTURING

The Engine House specialises in the production of low volume plastic parts using 3D printing. We thrive on creating parts for our clients that exceed expectations by using the latest SLS & SLA 3D printing technology, we are experts at bringing your ideas to life.

Years of experience have enabled us to master both our 3D Printing and the post processing techniques to achieve near perfect plastic parts with minimal layer lines without compromising our short lead times for production runs.

Our ambition is to create accurate, tough and cost effective parts using additive manufacturing that can compete with traditional manufacturing methods such as injection moulding and CNC machining while simultaneously reducing the need for minimum order quantities.

The Engine house are not just capable of manufacturing thousands of parts but will also 3D print one off prototypes, upload your parts or STL files to view an instant quote.

Small Batch Run

Low volume production doesn't have to be a hard choice. With our small batch production and no minimum order quantity, you can order one part or 100. No tooling or set up costs.

ONE OFF PARTS

You will need to have an STL before you can use the instant quoting portal. Brilliant for one off parts in need of express turnaround with a choice of materials. No tooling or set up costs.

Order prints now

Ordering has never been easier. Take advantage of our centralised order portal to manage and track your orders in real time. Stay on top of status updates, order history, and more.

NYLON 11 powder

Nylon 11 Powder is ideal for:

*Impact-resistant prototypes, jigs, and fixtures

*Thin-walled ducts and enclosures

*Snaps, clips, and hinges

*Orthotics and prosthetics*

Low Volume Batch Runs

Taking every stage of your design into consideration, The Engine House can offer continuous small batch production runs of your design or alternatively use research, design and integrity testing to find the most effective manufacturing method for full-scale production.

Low Force Stereolithography Materials

Standard Resins

Our standard resins are available in black, grey & white, our standard materials are also the most popular not only because of their durability but also being so versatile to use in many industries. After post processing your parts will have a matt texture that can be used as the final finish or be used as the perfect surface for custom spraying or painting

Engineering Resins

From elastic resins of 50A shore for medical & wearables devices to high temp resins able to resist in excess of 230°C the engineering range of resins are perfect for the most unique projects that require a cost effective way to prototype or even print a completely finished part

Jewelry & Casting

High temperature resin can be used to make detailed rubber moldings for repeating products or take on a modern approach to traditional jewellery making by using wax resins to create detailed investment castings of your designs.

Technique & Processing

Printing in SLA requires placement of supports to ensure the printing is accurate & successful, our expert team will place the supports in a way to not disrupt the design of the part.

Once the print is complete, our unique post-processing technique will ensure a perfect finish with minimal polishing required